There are many types of gel hot and cold packs without any bubbles in the market, especially transparent packing, it's easy to find that.

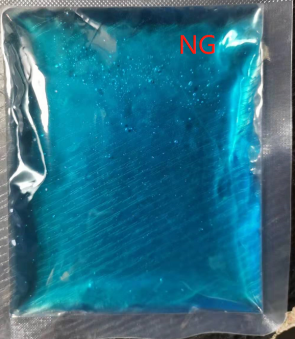

In our factory, last week, one of Automatic Vacuum-packer is wrong with their work for appearing bubbles, you know, we judged these hot and cold packs to be unqualified. In order to solve this issue, we sent the vacuumed to repair. The engineer initially analyzed the reason for the pump, so they plan to use imported pump for verification, if it still can’t be used to clean bubbles from gel pack, it may cause by others. So we’re waiting for the final results in the following days.

The principle is also relatively simple. Because food mildew and spoilage are mainly caused by the activities of microorganisms, the survival of most microorganisms (such as molds and yeasts) is Oxygen is needed, and vacuum packaging uses this principle to extract oxygen in the packaging bag and food cells, so that microorganisms lose their living environment. Experiments have proved that when the oxygen concentration in the packaging bag is less than or equal to 1%, the growth and reproduction speed of microorganisms will drop sharply. When the oxygen concentration is less than or equal to 0.5%, most microorganisms will be inhibited and stop reproducing. (Note: Vacuum packaging cannot inhibit the growth of anaerobic bacteria and the deterioration and discoloration of food caused by enzyme reactions, so it needs to be combined with other auxiliary methods, such as refrigeration, quick freezing, dehydration, high temperature sterilization, irradiation sterilization, microwave sterilization, salt Pickling, etc.)

Because fats and oils contain a large amount of unsaturated fatty acids, they are oxidized by the action of oxygen, which makes the food taste bad. Deterioration, in addition, oxidation also causes the loss of vitamin A and C, and the unstable substances in food pigments are affected by oxygen to darken the color. Therefore, deoxygenation can effectively prevent food from spoiling.

3. Besides the oxygen-removing and quality-preserving functions of vacuum packaging, vacuum inflatable packaging also has the functions of pressure resistance, gas barrier, and preservation, which can more effectively maintain the original color, aroma, taste and shape of food for a long time. And nutritional value.

Such as crispy and fragile foods, foods that are easy to agglomerate, foods that are easy to deform and run out of oil, foods with sharp edges or corners or high hardness that will pierce the packaging bag. After the food is vacuum-filled, the air pressure inside the packaging bag is stronger than the atmospheric pressure outside the packaging bag, which can effectively prevent the food from being crushed and deformed under pressure without affecting the appearance of the packaging bag and printing decoration.

The nitrogen is an inert gas, which plays a filling role and keeps positive pressure inside the bag to prevent air outside the bag from entering the bag and protect the food. The carbon dioxide can dissolve in various fats or water, and it can be turned into weakly acidic carbonic acid, which has the activity of inhibiting molds, spoilage bacteria and other microorganisms. The oxygen can inhibit the growth and reproduction of anaerobic bacteria, and keep the freshness and color of fruits and vegetables. The high concentration of oxygen can keep fresh meat in its bright red color. The machine has good vacuum performance and is suitable for vacuum packaging of multiple plastic bags. The machine is small in size, simple in structure and easy to use. The sealed food can prolong the fresh-keeping period at room temperature, which can effectively prevent the food in the refrigerator from odor, deterioration, dehydration and cracking. This machine applies vacuum to items or food that need to be stored for a long time, such as medical supplies, electronic devices, audio-visual products, cameras, woolen clothes, gold and silver jewelry, antique calligraphy and painting, dried and fresh fruits, tea, raw and cooked meat, etc. After encapsulation, it can effectively play the role of freshness, quality, moisture, mildew, rust, pollution, oxidation and vacuum sterilization, thereby extending the shelf life. The various soft-packaged foods encapsulated by this machine are convenient to carry and suitable for field operations and business trips.

Contact: Cindy

Phone: +0086 21-57762817

Tel: 021-57762817

Whatsapp: +0086 17621490604

Email: info@shwarmmer.com

Add: No.33, 618 Dingyuan Rd Songjiang Shanghai China, 201616

We chat